Differentials are crucial components enabling wheels to rotate at varying speeds‚ vital for cornering and traction. They transmit engine power to axles.

The differential’s primary function is power transmission‚ speed reduction‚ and maintaining traction‚ especially in automotive systems.

Understanding differential parts – like the ring gear – is key to grasping its operation within a motor vehicle’s drivetrain.

What is a Differential?

A differential is a set of gears housed within a vehicle’s axle‚ designed to allow the wheels on the same axle to rotate at different speeds. This is fundamentally important when navigating turns‚ as the outer wheel travels a greater distance than the inner wheel. Without a differential‚ the wheels would bind‚ causing instability and tire wear.

Essentially‚ it distributes torque from the engine to the wheels‚ managing speed variations. Key parts include the ring gear‚ pinion gear‚ spider gears‚ and side gears‚ all working in concert to achieve this function. It’s an integral component for smooth and controlled vehicle operation.

Importance in Automotive Systems

The differential is paramount to the safe and efficient operation of most vehicles‚ particularly those with rear or four-wheel drive. It prevents binding during turns‚ ensuring stable handling and minimizing tire scrubbing. By allowing wheels to spin at different rates‚ it maximizes traction‚ especially on uneven surfaces.

Without a functioning differential‚ cornering would be difficult and potentially dangerous. Its function in power transmission and speed reduction is also critical. The differential’s robust design and reliable performance contribute significantly to overall vehicle durability and drivability.

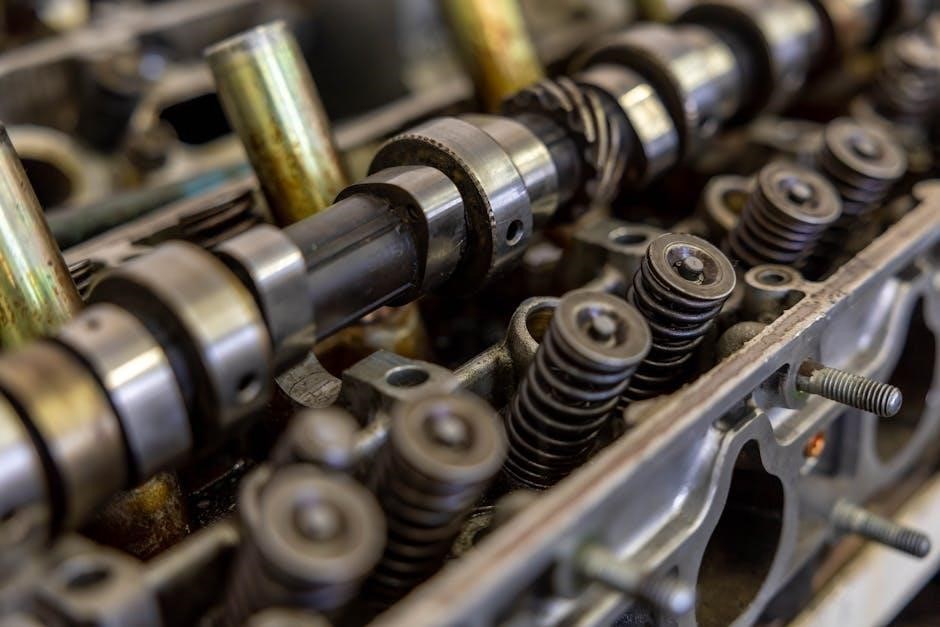

Key Components of a Differential

Key parts include the ring gear‚ pinion gear‚ differential case‚ side gears‚ pinion shaft‚ and spider gears – all working together for smooth operation.

Ring Gear and Pinion Gear

The ring gear and pinion gear initiate the differential’s power transfer. The pinion‚ driven by the driveshaft‚ meshes with the larger ring gear‚ causing it to rotate.

This initial gear reduction significantly increases torque. The ring gear is attached to the differential case‚ transferring power to the side gears. Their robust construction resists speed and load.

Essentially‚ the pinion’s rotational force is converted into a 90-degree turn by the ring gear‚ enabling power delivery to the axles. Proper meshing is crucial for efficiency and longevity‚ preventing excessive wear.

Differential Case

The differential case serves as the central housing for the entire differential assembly. It directly receives rotational force from the ring gear‚ encapsulating and supporting all internal components.

This robust casing rotates with the ring gear‚ transmitting power to the side gears and ultimately‚ the axles. It’s designed to withstand significant stress and maintain precise alignment.

The case’s structural integrity is paramount for efficient power delivery and minimizing vibration. Bearings within the case ensure smooth rotation and reduce friction‚ contributing to overall drivetrain efficiency.

Side Gears

Side gears‚ also known as sun gears‚ are crucial components directly connected to the axles of a vehicle. They receive power from the spider gears within the differential case.

These gears transmit torque to the corresponding wheels‚ allowing them to rotate. Importantly‚ side gears facilitate differing rotational speeds between the wheels – essential for cornering.

Their design allows for independent wheel movement while still receiving power. The side gears’ strength and precision are vital for reliable power transfer and preventing drivetrain failures. They are key to differential function.

Pinion Shaft

The pinion shaft is a critical element in the differential‚ responsible for receiving power directly from the driveshaft. It’s a small gear that meshes with the larger ring gear‚ initiating the power transfer process.

This shaft’s robust construction is essential‚ as it withstands significant torque loads. The pinion shaft’s angle and gear ratio influence the overall speed reduction and torque multiplication within the differential.

Proper alignment and lubrication of the pinion shaft are vital for efficient operation and longevity‚ preventing premature wear and ensuring smooth power delivery to the vehicle’s wheels.

Spider Gears (or Pinion Gears)

Spider gears‚ also known as pinion gears within the differential‚ play a pivotal role in allowing wheels to rotate at different speeds during turns. These smaller gears are mounted on a cross-pin within the differential case.

They transmit torque from the ring gear to the side gears‚ and crucially‚ they accommodate speed differences between the wheels. When cornering‚ the outer wheel travels a greater distance‚ requiring a faster rotation.

The spider gears facilitate this by allowing one side gear to rotate faster while the other slows down‚ ensuring smooth and controlled vehicle handling.

How a Differential Works

Differentials distribute torque to wheels‚ enabling varied rotational speeds during turns while maintaining power transmission. Spider gears are central to this function.

Understanding Torque Distribution

Torque distribution within a differential is a fascinating process. The system doesn’t simply split power 50/50; instead‚ it dynamically allocates torque based on wheel resistance.

When a vehicle corners‚ the outer wheel needs to travel a greater distance than the inner wheel. The differential allows this by sending more torque to the wheel encountering less resistance – typically the inner wheel.

This ensures smooth cornering and prevents wheel slippage. The spider gears play a critical role in facilitating this variable torque distribution‚ adapting to changing road conditions and driving scenarios.

Essentially‚ the differential directs power to where it’s needed most‚ maximizing traction and vehicle control.

Allowing Wheel Speed Differences

A core function of the differential is enabling wheels to rotate at different speeds‚ a necessity during turns. Without it‚ tires would scrub‚ causing instability and tire wear.

When a vehicle navigates a corner‚ the outer wheel covers more ground than the inner wheel. The differential accommodates this difference by permitting the outer wheel to spin faster.

This is achieved through the ingenious design of spider gears‚ which allow for varying rotational speeds while still transmitting power. This prevents binding and ensures a smooth‚ controlled driving experience.

The differential’s ability to manage speed discrepancies is fundamental to vehicle handling and efficiency.

The Role of Spider Gears in Cornering

Spider gears‚ also known as pinion gears‚ are central to a differential’s cornering ability. They facilitate the speed difference between the wheels during turns‚ allowing the outer wheel to rotate faster.

As a vehicle corners‚ these gears rotate on their axes‚ effectively distributing torque unevenly. This allows the wheel with less resistance – the outer wheel – to spin more freely.

Without spider gears‚ the wheels would be forced to rotate at the same speed‚ leading to tire slippage and compromised handling. They are crucial for smooth and efficient cornering.

Their design ensures power delivery while accommodating differing wheel speeds.

Types of Differentials

Differentials vary from open to limited-slip‚ locking‚ and electronic types‚ each offering unique traction and performance characteristics for various vehicle needs.

These designs impact power distribution and handling‚ adapting to diverse driving conditions and vehicle applications.

Open Differential

Open differentials represent the most common and simplest design‚ functioning by allowing each wheel on an axle to rotate at different speeds. This is achieved through the use of spider gears‚ facilitating smooth cornering by compensating for varying wheel travel distances.

However‚ a key drawback is that if one wheel loses traction – encountering ice or lifting off the ground – all power will be directed to that wheel‚ leaving the other with no drive. This can significantly hinder vehicle progress in challenging conditions. The system’s inherent simplicity makes it cost-effective‚ but less capable in demanding scenarios.

Limited-Slip Differential (LSD)

Limited-slip differentials (LSDs) address the open differential’s weakness by restricting the amount of speed difference between the wheels. They employ various mechanisms – clutches‚ gears‚ or viscous couplings – to transfer some torque to the wheel with better traction when one wheel begins to slip.

This prevents complete power loss to a single wheel‚ improving performance in low-traction situations. While not fully locking‚ LSDs offer a balance between open differential smoothness and enhanced traction. They are commonly found in performance vehicles and off-road applications‚ providing improved stability and control.

Locking Differential

Locking differentials represent the most aggressive approach to traction control‚ forcing both wheels to rotate at the same speed‚ regardless of traction differences. This is achieved through a mechanism that physically locks the side gears to the differential case.

While providing maximum traction in extreme conditions – like deep mud or rock crawling – locking differentials are generally not suitable for on-road use. They can cause binding‚ increased steering effort‚ and potential drivetrain damage on paved surfaces due to the elimination of wheel speed differentiation during cornering.

Electronic Differential

Electronic differentials utilize sensors and actuators to mimic the function of mechanical limited-slip or locking differentials‚ but with greater precision and adaptability. These systems typically employ wheel speed sensors and‚ often‚ throttle position and steering angle sensors.

By selectively applying braking force to a spinning wheel‚ the electronic differential effectively transfers torque to the wheel with more traction. This provides enhanced stability and control‚ particularly during cornering or on slippery surfaces‚ without the drawbacks of fully locking systems. They offer a smooth and refined driving experience.

Differential Assembly and Function

Differential assembly involves precise bearing installations – axle and differential – ensuring smooth operation. Its core function is to distribute torque efficiently to the wheels.

Axle Bearing Assembly

Axle bearing assembly is a critical step within the differential’s overall construction‚ directly impacting vehicle performance and longevity. These bearings support the axle shafts‚ allowing for smooth rotation while simultaneously bearing the vehicle’s weight and handling substantial forces.

Proper installation‚ utilizing correct tolerances and lubrication‚ is paramount to prevent premature wear and potential failure. The assembly ensures the axles spin freely within the differential housing‚ minimizing friction and maximizing power transfer. Careful attention to detail during this phase contributes significantly to a quiet and reliable drivetrain.

Differential Bearing Assembly

Differential bearing assembly involves precisely mounting bearings within the differential case to support the pinion and ring gears; These bearings are crucial for minimizing friction and ensuring smooth‚ quiet operation of the differential. Correct pre-load adjustment is vital; too little allows excessive play‚ while too much generates heat and accelerates wear.

High-quality bearings and meticulous installation are essential for reliable power transmission. The assembly directly influences the efficiency and lifespan of the entire differential system‚ impacting overall vehicle performance and reducing the risk of costly repairs.

Functions of the Differential System

Differential systems transmit engine power‚ reduce speed‚ and maintain traction by allowing wheels to rotate independently‚ crucial for vehicle handling and stability.

Power Transmission

Power transmission is a core function of the differential‚ receiving rotational force from the driveshaft and distributing it to the axle shafts. This process isn’t a simple one-to-one transfer; the differential cleverly manages the power split.

The ring and pinion gear set initially reduces the engine’s speed and increases torque. Subsequently‚ the differential case and spider gears facilitate the transfer of this adjusted power to the side gears‚ ultimately driving the wheels.

Effectively‚ the differential acts as a crucial intermediary‚ ensuring consistent power delivery even when wheel speeds differ‚ maintaining vehicle momentum and control.

Speed Reduction

Speed reduction is a fundamental aspect of the differential’s operation‚ achieved primarily through the interaction of the ring gear and pinion gear. The pinion gear‚ connected to the driveshaft‚ meshes with the larger ring gear‚ causing a significant decrease in rotational speed.

This reduction is essential because engines typically operate at higher RPMs than ideal for wheel rotation. The gear ratio determines the extent of this speed decrease‚ influencing both torque and overall vehicle performance.

This process allows for optimal power delivery and control‚ especially during acceleration and varying terrain conditions.

Maintaining Traction

Maintaining traction is a critical function of the differential‚ particularly when encountering uneven surfaces or during cornering. By allowing wheels to rotate at different speeds‚ the differential prevents wheel slippage‚ ensuring optimal grip.

When one wheel loses traction‚ the differential redirects power to the wheel with more grip‚ maximizing forward momentum. This is especially important in four-wheel and all-wheel drive vehicles.

Without a differential‚ both wheels would be forced to rotate at the same speed‚ leading to reduced control and potential loss of traction.

Common Differential Problems

Common issues include noise‚ vibration‚ gear wear‚ and oil leaks‚ stemming from worn components or insufficient lubrication. These affect performance and require prompt attention.

Noise and Vibration

Unusual noises – whining‚ humming‚ or clunking – often indicate differential problems. These sounds frequently originate from worn gears‚ bearings‚ or insufficient lubrication within the differential assembly.

Vibration can accompany the noise‚ signaling damaged internal parts. Gear wear‚ specifically on the ring and pinion‚ is a common culprit. Axle bearing issues can also contribute to both noise and vibration. Regular fluid checks and component inspections are crucial for early detection and prevention of escalating damage.

Ignoring these symptoms can lead to complete differential failure.

Gear Wear

Gear wear within the differential is a significant concern‚ stemming from friction‚ contamination‚ or inadequate lubrication. The ring and pinion gears‚ crucial for power transmission‚ are particularly susceptible to wear over time.

Symptoms include increased noise‚ reduced power transfer‚ and potential vibration. Worn gears create metal particles that circulate within the differential‚ accelerating further damage to other parts.

Regular differential fluid changes and inspections are vital to mitigate wear. Addressing issues promptly prevents catastrophic failure of the differential assembly.

Oil Leaks

Oil leaks from a differential are a common issue‚ often originating from worn seals or gaskets. These leaks reduce lubrication‚ accelerating wear on critical parts like the pinion and ring gears‚ and potentially leading to differential failure.

Common leak locations include the pinion seal‚ differential case gaskets‚ and axle seals. Reduced oil levels compromise the differential’s function‚ increasing friction and heat.

Promptly addressing oil leaks through seal or gasket replacement is crucial for maintaining the differential assembly’s integrity and preventing costly repairs.

Differential Maintenance

Regular fluid checks and changes are vital for differential longevity. Inspecting components for wear‚ leaks‚ and proper operation ensures optimal function;

Fluid Checks and Changes

Differential fluid is critical for lubrication and heat dissipation within the gear system. Regularly checking the fluid level – typically through a fill plug – is essential. Look for a clean‚ honey-colored appearance; milky or metallic-flecked fluid indicates contamination or wear.

Fluid changes should follow the vehicle manufacturer’s recommended intervals‚ often between 30‚000 and 60‚000 miles. Using the correct gear oil weight is paramount for proper differential function. Proper fluid maintenance minimizes gear wear and prevents costly repairs‚ ensuring smooth power transfer and optimal performance.

Inspection of Components

Regular inspection of differential parts is vital for preventative maintenance. Examine the ring and pinion gears for signs of wear‚ pitting‚ or excessive backlash. Check the spider gears and side gears for damage‚ ensuring smooth rotation within the differential case.

Inspect axle bearings for play or roughness‚ as these can indicate impending failure. Look for any oil leaks around seals and gaskets. A thorough visual assessment‚ combined with a listening check for unusual noises‚ can reveal potential issues before they escalate into major repairs‚ maintaining optimal function.

Differential in Different Vehicles

Differentials adapt to various drive systems; rear-wheel drive‚ four-wheel drive‚ and all-wheel drive vehicles utilize them for power distribution and wheel speed management.

Rear-Wheel Drive Vehicles

Rear-wheel drive vehicles prominently feature a traditional differential setup. This system efficiently transmits power from the engine‚ through the driveshaft‚ and ultimately to the rear axles.

The differential allows the rear wheels to rotate at different speeds‚ crucial during turns where the outer wheel travels a greater distance. Key parts‚ like the ring and pinion gears‚ manage speed reduction and torque transfer.

Without a differential‚ binding would occur during cornering‚ causing instability and tire wear. The differential’s function is paramount for smooth‚ controlled handling in these vehicles‚ ensuring optimal traction and driving experience.

Four-Wheel Drive Vehicles

Four-wheel drive vehicles often employ more complex differential systems than rear-wheel drive counterparts. They typically utilize a transfer case alongside differentials to distribute power to both front and rear axles.

These systems frequently incorporate a center differential‚ allowing speed differences between the front and rear axles‚ preventing drivetrain binding. Understanding differential parts – like spider gears – is vital for comprehending torque distribution.

The function of these differentials is to provide enhanced traction on varied terrains‚ while still permitting independent wheel speeds for optimal handling and control during off-road conditions.

All-Wheel Drive Vehicles

All-wheel drive (AWD) vehicles utilize differentials to manage power distribution across all four wheels‚ offering superior traction and stability. Unlike traditional 4WD‚ AWD systems are often full-time‚ continuously adjusting torque.

These systems frequently employ viscous couplings or electronic control units to vary differential operation‚ responding to wheel slip and road conditions. Knowing differential parts‚ such as the ring gear‚ aids understanding.

The core function is to enhance grip and handling on diverse surfaces‚ automatically adapting to maintain optimal performance and driver control‚ improving safety and responsiveness.