Single Phase Motor Wiring Diagram with Capacitor Start PDF: A Comprehensive Plan

This detailed PDF guide unravels the complexities of capacitor-start motors, offering clear wiring diagrams and troubleshooting advice for efficient single-phase motor operation and maintenance.

Capacitor-start motors represent a clever solution to the inherent starting difficulties of single-phase induction motors. Unlike their direct-on-line counterparts, these motors utilize an auxiliary winding and a capacitor to generate the necessary phase shift for initial rotation. This phase shift creates a rotating magnetic field, providing the torque needed to overcome static friction and initiate movement.

Understanding these motors is crucial for anyone involved in electrical maintenance, repair, or design. They are commonly found in applications requiring moderate starting torque, such as compressors, pumps, and fans. A comprehensive wiring diagram is essential for safe installation, efficient operation, and effective troubleshooting. This guide will delve into the intricacies of capacitor-start motors, providing a detailed exploration of their components, wiring configurations, and potential issues. We will focus on providing a clear, accessible resource – a capacitor start motor wiring diagram PDF – to empower users with the knowledge to confidently work with these systems.

Understanding Single Phase Motor Basics

Single-phase motors operate on a single alternating current (AC) supply, making them prevalent in residential and light commercial applications. However, unlike three-phase motors which inherently produce a rotating magnetic field, single-phase motors require assistance to initiate rotation. When energized, a single-phase motor produces a pulsating, rather than rotating, magnetic field.

This pulsating field can be visualized as alternating north and south poles, lacking the directional impetus for self-starting. Consequently, auxiliary methods, like capacitor-start configurations, are employed to create a phase difference, effectively simulating a rotating field. A thorough grasp of these fundamental principles is vital when interpreting a capacitor start motor wiring diagram PDF. Understanding how these motors function, and why they need assistance starting, is key to successful installation and repair. This foundational knowledge will underpin our exploration of more complex wiring schemes.

Why Use a Capacitor Start Configuration?

Capacitor-start configurations address the inherent starting limitations of single-phase motors. By introducing a capacitor into the circuit, a phase shift is created between the currents flowing through the main and auxiliary windings. This phase shift generates a temporary, second rotating magnetic field, providing the necessary torque to overcome static friction and initiate motor rotation.

Once the motor reaches a certain speed – typically 75-80% of its rated speed – the capacitor is often switched out of the circuit, allowing the motor to run on the main winding alone. This configuration offers a high starting torque, making it suitable for applications requiring substantial initial power. Studying a capacitor start motor wiring diagram PDF reveals how this clever arrangement effectively transforms a non-self-starting motor into a reliable power source. It’s a cost-effective solution for many applications.

Components of a Capacitor Start Motor System

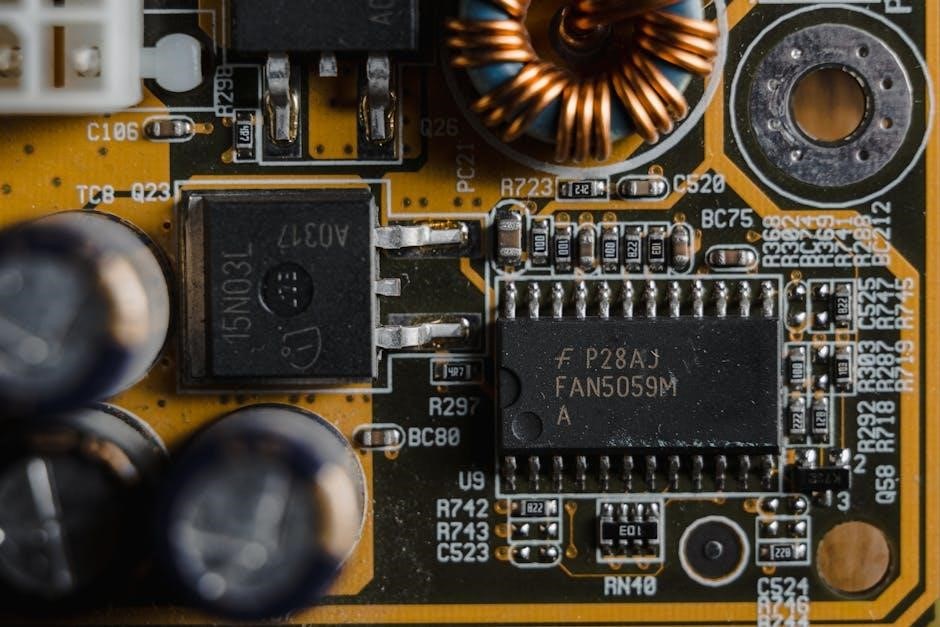

A capacitor-start motor system comprises several key components working in harmony. These include the stator windings – a main winding for running and an auxiliary (or starting) winding – crucial for generating the rotating magnetic field. The rotor construction, typically a squirrel-cage design, responds to this field, initiating rotation.

Central to the system is the start capacitor, available in various types (oil-filled, electrolytic) and ratings, dictating the starting torque. A wiring diagram PDF illustrates how these components interconnect. Centrifugal switches automatically disconnect the capacitor and auxiliary winding once the motor reaches operating speed. Understanding each component’s role, as detailed in a capacitor start motor wiring diagram, is vital for effective troubleshooting and maintenance, ensuring optimal performance and longevity of the motor.

Stator Windings (Main & Auxiliary)

The stator, the stationary part of the motor, houses two crucial windings: the main and auxiliary windings. The main winding, designed for continuous operation, possesses a higher resistance and fewer turns, enabling sustained torque production. Conversely, the auxiliary winding, utilized solely during startup, features lower resistance and more turns, creating a leading phase shift.

A capacitor start motor wiring diagram PDF clearly depicts their arrangement. This phase shift, induced by the start capacitor, generates the necessary rotating magnetic field to initiate motor rotation. Once running, a centrifugal switch disconnects the auxiliary winding, leaving only the main winding energized. Understanding the differing characteristics and functions of these windings, as illustrated in detailed diagrams, is fundamental to comprehending the motor’s operational principles.

Rotor Construction

The rotor, the rotating component within a single-phase capacitor-start motor, is typically a squirrel-cage design. This construction consists of conductive bars – usually aluminum or copper – embedded within slots in a laminated steel core and shorted at both ends by end rings. A capacitor start motor wiring diagram PDF won’t usually detail the internal rotor construction, but understanding it is vital.

This arrangement creates a closed electrical circuit. When the rotating magnetic field from the stator windings cuts across these rotor bars, it induces a current, generating a torque that causes the rotor to spin. The simplicity and robustness of the squirrel-cage rotor contribute to the motor’s reliability and low maintenance requirements. The laminated core minimizes eddy current losses, enhancing efficiency.

Start Capacitor – Types and Ratings

Start capacitors, crucial components in a capacitor-start motor, are primarily electrolytic capacitors designed for intermittent duty. A capacitor start motor wiring diagram PDF will indicate the required capacitance and voltage rating. These capacitors provide a significant phase shift to initiate rotation, but are disconnected once the motor reaches a certain speed – typically 75-80% of its rated speed – to prevent overheating.

Oil-filled capacitors are also used, offering higher voltage and temperature ratings. Ratings are specified in microfarads (µF) for capacitance and volts AC (VAC) for voltage. Selecting the correct rating is vital; an undersized capacitor won’t provide sufficient starting torque, while an oversized one can damage the winding. Always refer to the motor’s nameplate or wiring diagram for the precise specifications.

Capacitor Functionality: A Deep Dive

Understanding capacitor functionality is key when interpreting a capacitor start motor wiring diagram PDF. A capacitor, fundamentally, stores electrical energy in an electric field, created between two conductive plates separated by an insulating dielectric. This storage capability is leveraged in single-phase motors to create a phase shift, essential for initiating rotation.

Capacitors accumulate charge when voltage is applied, releasing it when needed. The capacitance, measured in Farads (F), dictates the amount of charge stored at a given voltage. The dielectric material influences capacitance and voltage rating. Properly functioning capacitors are vital; a failing capacitor will hinder motor starting and potentially cause damage. Examining a capacitor start motor wiring diagram helps visualize this interaction.

What is a Capacitor? – Definition and Principles

A capacitor is a passive electronic component with two terminals, designed to store electrical energy within an electric field. It’s essentially comprised of two conducting plates separated by an insulating material, known as a dielectric. This construction allows for the accumulation of electric charge, creating a potential difference – voltage – across the plates.

In the context of a capacitor start motor wiring diagram, understanding this principle is crucial. Capacitors oppose changes in voltage, storing energy and releasing it as needed. Early examples, like the Leyden Jar, demonstrated this basic functionality. They function by accumulating charges, and are often referred to as condensers; Their ability to store and distribute energy is fundamental to the operation of these motors.

How Capacitors Store Electrical Energy

Capacitors store electrical energy by accumulating electric charges on their plates when a voltage is applied. This process doesn’t involve the flow of current through the capacitor, but rather a build-up of charge on the conductive surfaces. The dielectric material between the plates prevents direct current flow, enabling charge storage.

Within a capacitor start motor wiring diagram, this stored energy is vital for creating the phase shift necessary to initiate rotation. As voltage is applied, electrons accumulate on one plate, creating a negative charge, while the other plate loses electrons, becoming positively charged. This charge separation establishes an electric field, representing stored potential energy. The amount of energy stored depends on the capacitance and the voltage applied, making capacitor selection critical for optimal motor performance.

Capacitor Characteristics: Capacitance, Voltage Rating, and Tolerance

Understanding capacitor characteristics is crucial when interpreting a capacitor start motor wiring diagram. Capacitance, measured in Farads, dictates the capacitor’s ability to store charge; higher capacitance means more stored energy. Voltage rating specifies the maximum voltage the capacitor can withstand without breakdown – exceeding this risks failure and potential safety hazards.

Tolerance indicates the permissible deviation from the stated capacitance value. For motor applications, precise capacitance is often needed for optimal starting torque. Selecting a capacitor with an appropriate voltage rating and tolerance ensures reliable motor operation. Incorrect values can lead to insufficient starting torque, overheating, or even damage to the motor or capacitor itself. Always refer to the motor’s specifications when choosing a replacement capacitor for your wiring diagram.

Capacitor Start Wiring Diagram – Basic Overview

A capacitor start wiring diagram illustrates how a capacitor is integrated into a single-phase motor circuit to provide starting torque. The core principle involves using the capacitor to create a phase shift in the auxiliary winding’s current, generating a rotating magnetic field. This field interacts with the rotor, initiating rotation.

Typically, the diagram will show the start winding, run winding, capacitor, and centrifugal switch connected in a specific configuration. The centrifugal switch disconnects the capacitor once the motor reaches a certain speed, leaving only the run winding energized. Understanding this basic layout is fundamental before delving into detailed diagrams. A clear diagram is essential for safe and effective motor wiring, ensuring proper functionality and preventing damage.

Detailed Wiring Diagram Explanation

The wiring diagram reveals the start winding connects in parallel with the main (run) winding, but crucially, includes a series capacitor. This capacitor shifts the phase of the current in the start winding, creating the necessary phase difference for starting torque. A centrifugal switch, mechanically linked to the motor shaft, is placed in series with the start winding and capacitor.

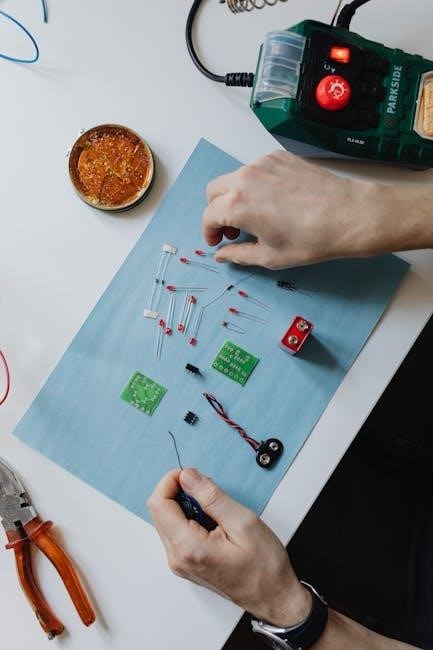

Upon startup, both windings are energized, providing high starting torque. As the motor accelerates, the centrifugal switch opens, disconnecting the capacitor and start winding. Only the run winding remains active for continuous operation. Safety is paramount: ensure proper grounding and insulation. Incorrect wiring can lead to motor failure or electrical hazards. Always disconnect power before working on the wiring.

Connecting the Start Winding and Capacitor

The start winding, possessing higher resistance, is connected in series with the start capacitor. This configuration is vital for generating the leading current phase needed to initiate rotation. The capacitor’s positive terminal typically connects to one end of the start winding, while the other end connects to the common neutral point of the power supply. Precise capacitor value selection is crucial; an incorrect value can hinder starting or cause overheating.

Ensure the capacitor’s voltage rating exceeds the maximum voltage encountered in the circuit. The connection must be secure and insulated to prevent short circuits. Remember, the start winding is only energized during startup, thanks to the centrifugal switch, so the capacitor is temporarily in the circuit. Proper connection guarantees the phase shift necessary for self-starting.

Connecting the Run Winding

The run winding, designed for continuous operation, is directly connected to the power supply. One terminal of the run winding connects to the live (hot) wire of the power source, while the other connects to the same common neutral point as the start winding/capacitor combination. This direct connection ensures a consistent magnetic field for sustained motor rotation once started.

Unlike the start winding, the run winding remains energized throughout the motor’s operation. It’s typically constructed with fewer turns of thicker wire to minimize resistance and maximize efficiency. Proper insulation of the run winding connections is paramount to prevent electrical hazards and ensure long-term reliability. The run winding provides the primary torque for maintaining the motor’s speed.

Power Supply Connection and Safety Considerations

Connecting the power supply requires strict adherence to electrical safety protocols. Always disconnect power at the breaker before commencing any wiring work. The power supply, typically single-phase 230V or 120V, connects to the main terminals of the motor circuit. Ensure proper grounding of the motor frame to prevent electric shock hazards. Use appropriately sized wiring and connectors rated for the motor’s current draw.

Capacitors store electrical charge even when power is off; discharge them before handling. Double-check all connections for tightness and correct polarity. Never work on live circuits. Employ a qualified electrician if you are unfamiliar with electrical wiring. A correctly fused circuit protects against overloads and short circuits, safeguarding both the motor and the power supply.

Different Capacitor Start Wiring Configurations

Several wiring configurations utilize the capacitor-start principle, each with unique characteristics. The Split-Phase Capacitor Start method employs a capacitor solely during the starting phase, disconnecting it once the motor reaches a certain speed, offering a simpler design. This configuration provides a higher starting torque compared to standard split-phase motors.

Conversely, the Capacitor Start, Capacitor Run configuration maintains the capacitor in the circuit continuously. This improves running efficiency and power factor, alongside providing robust starting torque. Selecting the appropriate configuration depends on the application’s demands – considering factors like load requirements and desired efficiency levels. Detailed wiring diagrams for each configuration are crucial for correct implementation and optimal performance.

Split-Phase Capacitor Start

The Split-Phase Capacitor Start configuration is a common and relatively simple method for enhancing single-phase motor starting torque. It utilizes a start winding, alongside a capacitor connected in series with it, creating a phase shift to initiate rotation. Crucially, this capacitor is only active during the starting process; a centrifugal switch disconnects it once the motor reaches approximately 75% of its rated speed.

Wiring diagrams for this configuration clearly illustrate the capacitor’s placement between the start winding and the power supply. This temporary phase shift generates the necessary torque to overcome static friction. Once running, the motor relies on its main winding. This setup offers a cost-effective solution for applications requiring moderate starting torque.

Capacitor Start, Capacitor Run

The Capacitor Start, Capacitor Run (CSCR) configuration represents a more sophisticated approach to single-phase motor operation, offering improved performance characteristics compared to simpler designs. Unlike split-phase capacitor start motors, CSCR systems employ two capacitors: a start capacitor for high starting torque and a run capacitor for continuous operation.

Wiring diagrams for CSCR motors demonstrate the start capacitor, switched out by a centrifugal switch after startup, and the run capacitor remaining in the circuit. The run capacitor enhances power factor and efficiency during normal operation. This configuration delivers smoother operation, reduced current draw, and increased overall efficiency, making it ideal for demanding applications. It’s a more expensive solution but provides superior performance.

Troubleshooting Common Issues

Diagnosing problems in capacitor-start motors requires a systematic approach. If the motor doesn’t start, check the capacitor for shorts or opens, verify the centrifugal switch is functioning correctly, and inspect wiring connections for looseness or corrosion. Overheating issues often point to capacitor failure, winding faults, or inadequate ventilation; a bulging or leaking capacitor is a clear indicator of a problem.

A persistent humming sound typically suggests the start winding is energized continuously, often due to a faulty centrifugal switch. Always disconnect power before inspecting components. Remember, capacitors can retain a charge even when power is off, so discharge them safely before handling. Careful observation and a multimeter are essential tools for effective troubleshooting.

Motor Doesn’t Start – Potential Causes

A failure to start in a capacitor-start motor often stems from several key areas. First, a defective start capacitor is a common culprit; check for bulges, leaks, or test with a capacitance meter. A malfunctioning centrifugal switch, responsible for disconnecting the start winding once the motor reaches a certain speed, can prevent proper operation. Open or shorted windings in either the start or run windings will also halt starting.

Furthermore, loose wiring connections or a tripped overload protector can interrupt the power supply. Verify the power supply voltage is correct and stable. Inspect the motor for any physical obstructions preventing rotation. Always prioritize safety by disconnecting power before any inspection or testing procedures are undertaken.

Overheating Issues and Capacitor Failure

Overheating in a capacitor-start motor frequently indicates underlying problems, often linked to capacitor health. A weakened or failing start capacitor can cause excessive current draw in the start winding, leading to heat buildup. Poor ventilation around the motor, restricting airflow, exacerbates this issue. Worn bearings create friction, increasing operating temperature.

Internal short circuits within the windings themselves generate significant heat. A damaged or improperly sized capacitor can also contribute to overheating. Regularly check the capacitor for physical signs of distress – bulging or leaking. Addressing overheating promptly prevents further damage and potential motor failure. Always disconnect power before inspection and consider professional assistance for complex issues.

Humming Sound – Identifying the Problem

A persistent humming sound in a capacitor-start motor often signals an inability to reach its intended running speed. This frequently points to a faulty start capacitor, preventing the motor from developing sufficient torque to overcome the load. Low voltage supply can also cause humming, as the motor struggles to initiate rotation. Worn motor bearings can produce a similar sound, though often accompanied by vibration.

A partially disconnected winding or internal short circuit within the windings can also be the culprit. Carefully inspect the wiring connections and capacitor for any signs of damage. If the humming persists after checking these components, a professional diagnosis is recommended to avoid further damage or safety hazards.

Selecting the Right Capacitor

Choosing the correct capacitor is crucial for optimal motor performance and longevity. The capacitor’s microfarad (µF) rating must match the motor’s specifications, typically found on the motor’s nameplate or in the wiring diagram. Voltage rating is equally important; it should exceed the maximum voltage the capacitor will experience during operation, providing a safety margin.

Capacitor type matters too – oil-filled capacitors are common, but film capacitors offer better reliability and lifespan. Consider the duty cycle; motors with frequent starts require capacitors designed for intermittent use. Incorrect capacitance can lead to starting failure, overheating, or reduced torque. Always prioritize a capacitor with a tolerance within the motor’s requirements for consistent operation.

Safety Precautions When Working with Capacitors

Capacitors store electrical energy, even when disconnected from power, posing a significant shock hazard. Always disconnect power to the motor circuit before handling any components, including capacitors. Discharge the capacitor using a properly insulated screwdriver with a resistor (around 10k ohms) across its terminals to safely dissipate stored energy.

Never touch the capacitor terminals with bare hands; Wear appropriate personal protective equipment (PPE), including insulated gloves and safety glasses. Avoid short-circuiting the capacitor as this can cause it to explode. Inspect capacitors for physical damage – bulging or leaking indicates a failed component. Dispose of old capacitors properly according to local regulations, as they may contain hazardous materials.

Obtaining a Capacitor Start Motor Wiring Diagram PDF

Numerous online resources offer downloadable Capacitor Start Motor Wiring Diagram PDFs. Reputable electrical engineering websites, motor manufacturer sites (like those for GE, Siemens, or WEG), and dedicated HVAC forums frequently host these diagrams. A targeted Google search using keywords like “capacitor start motor wiring diagram PDF,” “single phase motor schematic,” or “motor capacitor wiring” will yield many results.

Beware of untrustworthy sources and always verify the diagram’s accuracy against your specific motor model. Electrical textbooks and online learning platforms often include detailed wiring schematics. Consider purchasing a comprehensive electrical wiring guide for a reliable and organized collection of diagrams. Always prioritize diagrams that match your motor’s voltage and horsepower rating for safe and correct installation.

Resources for Further Learning

For a deeper understanding of single-phase motors and capacitor start wiring, explore resources from electrical engineering institutions like the IEEE. Online platforms such as All About Circuits and Electronics Tutorials provide comprehensive articles and tutorials on capacitor principles and motor operation. YouTube channels dedicated to electrical repair and DIY projects (e.g., Electrician U, The Engineering Mindset) offer visual demonstrations of wiring techniques.

Manufacturer websites often provide detailed technical manuals and application notes for their motors. Consider enrolling in online courses on electrical motor control through platforms like Coursera or Udemy. HVAC-specific forums and communities are valuable for troubleshooting and sharing practical knowledge. Remember to consult local electrical codes and regulations for safe and compliant installations.