True Freezer Temperature Control Manual: A Comprehensive Guide

This manual details the operation of True freezer digital temperature controllers, focusing on defrost settings and parameters, essential for optimal performance and longevity.

Understanding True Freezer Temperature Controllers

True freezer temperature controllers are sophisticated systems designed to maintain precise and consistent temperatures, crucial for food safety and preservation. These digital controllers manage the entire refrigeration cycle, encompassing compressor operation, defrost cycles, and alarm functions. They utilize various sensors to monitor internal freezer temperature and respond accordingly, ensuring optimal performance.

Understanding the controller’s core functions is paramount for effective operation. True employs both time-initiated and temperature-terminated defrost systems, adapting to varying freezer loads and environmental conditions. The controller’s programming allows for customization of defrost frequency and duration, maximizing energy efficiency while preventing ice buildup. Furthermore, the controller incorporates alarm systems to alert users to temperature deviations or equipment malfunctions, safeguarding stored products. Proper comprehension of these features enables proactive maintenance and troubleshooting, extending the freezer’s lifespan and minimizing downtime.

Controller Models and Variations

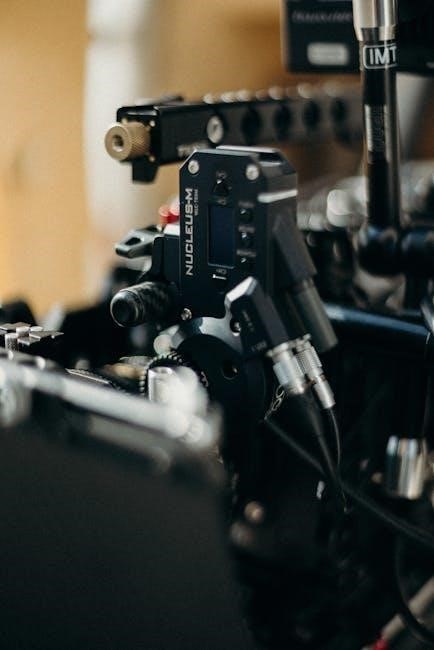

True freezer temperature controllers exhibit variations across different models, primarily distinguished by their feature sets and programming capabilities. Older models often feature simpler controls with basic temperature setting and defrost initiation, while newer digital controllers offer advanced functionalities like precise temperature monitoring, customizable defrost cycles, and comprehensive alarm systems.

The T-49F-HC-07 is a commonly encountered model, allowing temperature adjustment via set buttons and arrow keys. Variations exist in display types – some utilize LED displays, while others employ LCD screens for enhanced readability. Furthermore, controller versions may differ in their communication protocols, supporting remote monitoring and control through building management systems. Understanding the specific model number and its corresponding features is crucial for accurate operation and troubleshooting. Referencing the specific model’s documentation ensures proper utilization of its unique capabilities.

Initial Setup and Power-Up Procedures

Upon initial installation or after a power outage, True freezer temperature controllers require a specific setup procedure. First, verify the power supply voltage matches the controller’s requirements. Once powered on, allow the controller to complete its self-diagnostic check, indicated by a series of display messages or flashing lights.

Next, confirm the correct temperature display units (Fahrenheit or Celsius) are selected. If necessary, adjust this setting through the controller’s menu. It’s vital to ensure the temperature sensor is properly connected and functioning before proceeding. A brief period of stabilization is needed for the controller to accurately read the freezer’s internal temperature. Avoid immediately adjusting setpoints; allow the unit to reach a stable operating temperature before calibration or customization. Proper initial setup ensures accurate temperature control and efficient operation.

Temperature Display and Units

The True freezer temperature controller prominently displays the current internal freezer temperature. This reading is crucial for monitoring performance and ensuring food safety. The display utilizes a digital format, providing clear and precise temperature readings. Users can typically toggle between Fahrenheit (°F) and Celsius (°C) units to suit their preference or regional standards.

Accessing the unit selection is usually done through the controller’s menu system, often initiated by pressing and holding a designated “Set” or “Mode” button. The selected unit will then be consistently used for all temperature displays, setpoints, and alarm thresholds. Accurate interpretation of the displayed temperature relies on understanding the chosen unit. Regularly verifying the display’s functionality is recommended to ensure reliable temperature monitoring.

Setting the Desired Freezer Temperature

To set the desired freezer temperature, locate the “Set” button on the True freezer’s digital temperature controller. Press and hold this button until the temperature display begins to blink, indicating it’s in programming mode. Utilize the “Up” and “Down” arrow buttons to adjust the temperature to the desired level. Remember to consider the type of food being stored when selecting a temperature; generally, -10°F to 0°F (-23°C to -18°C) is recommended for optimal long-term preservation.

Once the desired temperature is displayed, press the “Set” button again to confirm the setting. The display will stop blinking, and the controller will begin maintaining the new setpoint. Regularly check the actual freezer temperature to ensure it aligns with the set value. Proper temperature setting is vital for food safety and energy efficiency.

Adjusting Temperature Setpoints

Adjusting temperature setpoints on a True freezer’s digital controller is crucial for maintaining optimal food preservation and energy efficiency. Begin by pressing and holding the “Set” button until the temperature display flashes. This activates the programming mode, allowing for adjustments. Use the “Up” and “Down” arrow buttons to incrementally change the setpoint to the desired temperature.

Small adjustments are recommended to avoid significant temperature fluctuations. After each adjustment, press “Set” again to confirm and save the new setpoint. Monitor the freezer’s temperature for a period to ensure stability. Consider the specific storage requirements of your contents when making adjustments; different foods benefit from varying temperatures. Regularly reviewing and fine-tuning setpoints ensures consistent performance.

Defrost Cycle Configuration

Defrost cycle configuration within a True freezer’s digital controller dictates how and when ice buildup is removed from the evaporator coils. True freezers commonly utilize both time-initiated and temperature-terminated defrost cycles, though temperature termination is prevalent. Configuration involves setting parameters like defrost frequency – how often the cycle runs – and duration – how long it lasts.

Accessing these settings typically requires navigating through the controller’s menu using the “Set” and arrow buttons. Understanding the interplay between time and temperature is vital; a properly configured cycle minimizes energy consumption while preventing excessive ice accumulation. Incorrect settings can lead to inefficient operation or inadequate defrosting. Regularly check defrost cycle performance to ensure optimal freezer function.

Defrost Initiation and Termination Methods

True freezer defrost cycles can begin in two primary ways: time-initiated or temperature-initiated. Time-initiated cycles start after a pre-set interval, regardless of ice buildup. Temperature-initiated cycles, however, activate based on the evaporator coil temperature, responding directly to frost accumulation. Termination methods are equally crucial.

A cycle can end either by time – running for a predetermined duration – or by temperature, ceasing when the evaporator coil reaches a specified temperature. True freezers often employ temperature-terminated defrost, offering greater efficiency. This method prevents unnecessary heating, saving energy. Proper configuration of both initiation and termination is vital for optimal performance, preventing both insufficient defrosting and wasted energy. Monitoring these settings ensures consistent freezer operation;

Temperature-Terminated Defrost Explained

Temperature-terminated defrost is a highly efficient method utilized in many True freezers. Unlike time-initiated defrost, this system doesn’t rely on a pre-set duration. Instead, the defrost cycle continues until the evaporator coil reaches a pre-defined termination temperature, typically around 40°F (4.4°C). This ensures complete ice removal without excessive energy consumption.

The controller continuously monitors the evaporator temperature via a sensor. Once the coil warms sufficiently, the defrost heater shuts off, and the evaporator fan restarts, distributing cool air. This method adapts to varying freezer loads and ambient conditions, optimizing defrost frequency. Properly functioning temperature sensors are critical for accurate termination. This intelligent approach minimizes defrost time, maximizing energy savings and maintaining consistent freezer temperatures.

Time-Initiated Defrost Settings

Time-initiated defrost operates on a pre-programmed schedule, regardless of actual ice buildup on the evaporator coil. While some True freezers utilize temperature termination, understanding time-initiated settings is crucial for certain models or as a fallback option. These settings involve configuring the defrost cycle’s frequency and duration.

Typically, you’ll find parameters to adjust the defrost interval – how often the cycle runs (e.g., every 8, 12, or 24 hours) – and the defrost duration – how long the heater operates (e.g., 20, 30, or 40 minutes). Shorter intervals prevent excessive ice, while longer durations ensure complete removal. Incorrect settings can lead to inefficient operation; too frequent defrosting wastes energy, while infrequent cycles cause ice buildup, reducing cooling capacity.

Alarm System Overview

True freezer temperature controllers incorporate a robust alarm system designed to alert operators to potential issues affecting product safety and equipment integrity. This system monitors critical parameters, triggering alarms when deviations occur. Understanding these alarms and their corresponding responses is vital for preventative maintenance and minimizing downtime.

The alarm system generally includes alerts for high and low temperatures, indicating potential cooling failures or door ajar situations. A door open alarm is particularly important, as prolonged door openings significantly raise internal temperatures. Proper configuration of alarm thresholds and acknowledgment procedures is essential. Ignoring alarms can lead to product spoilage, increased energy consumption, and potentially, compressor damage. Regular testing of the alarm functionality is recommended.

High and Low Temperature Alarms

High and low temperature alarms are critical safety features within the True freezer control system. These alarms activate when the internal freezer temperature deviates outside of the pre-set acceptable range, signaling a potential malfunction. A high-temperature alarm indicates a cooling system failure, potentially leading to product spoilage. Conversely, a low-temperature alarm might suggest a thermostat issue or excessive cooling, straining the compressor.

Alarm thresholds are configurable, allowing customization based on the specific storage requirements. Upon activation, the alarm typically triggers an audible and/or visual alert. Immediate investigation is crucial; check for door ajar situations, blocked vents, or compressor functionality. Documenting alarm events aids in identifying recurring problems and implementing preventative measures. Ignoring these alarms can result in significant product loss and costly repairs.

Door Open Alarm Configuration

The door open alarm is a vital feature designed to prevent temperature fluctuations and energy waste. This alarm activates when a freezer door remains open for a pre-determined duration, typically adjustable via the digital controller. Configuring this alarm involves setting the delay time – the period the door can be open before the alarm triggers. Shorter delays offer quicker alerts, while longer delays prevent false alarms from brief access.

Accessing the configuration menu usually requires pressing and holding a designated “Set” or “Menu” button. Navigation through the options utilizes up/down arrow keys. Ensure the selected delay aligns with typical operational needs. A properly configured door alarm minimizes temperature increases, preserving product integrity and reducing compressor workload. Regular testing of the alarm functionality is recommended to confirm its operational status.

Alarm Reset Procedures

Acknowledging and resetting alarms on a True freezer’s digital temperature controller is crucial for restoring normal operation after an event. When an alarm – high/low temperature or door open – activates, the controller typically displays a flashing indicator and may emit an audible signal. Resetting usually involves pressing a dedicated “Reset” or “Silence” button. However, simply silencing the alarm doesn’t always clear the underlying fault.

For temperature alarms, the condition must first resolve itself (temperature returning to the acceptable range) before a reset is possible. Door open alarms reset automatically once the door is closed, or manually via the reset button. Some models require a prolonged button press to confirm the reset. Always verify the alarm has cleared from the display after pressing the reset button, indicating the system is back to normal monitoring. Ignoring alarms can lead to product spoilage or equipment damage.

Sensor Calibration and Troubleshooting

Maintaining accurate temperature readings is paramount for True freezer performance, relying on properly calibrated sensors. Calibration ensures the controller displays the true freezer temperature, preventing spoilage or inefficient operation. If temperature discrepancies are suspected, begin by verifying the sensor is securely connected. Calibration procedures typically involve comparing the controller’s reading to a calibrated external thermometer.

Access calibration settings through the controller’s menu, adjusting the displayed value to match the reference thermometer. If calibration fails to resolve inaccuracies, the sensor itself may be faulty and require replacement. Troubleshooting inaccurate displays also includes checking for airflow obstructions around the sensor bulb. A damaged sensor or wiring can also cause erratic readings, necessitating professional repair or component replacement.

Temperature Sensor Types Used

True freezers commonly utilize thermistors as their primary temperature sensing component within the digital control systems. These sensors exhibit a significant change in electrical resistance proportional to temperature variations, providing accurate and reliable data to the controller. Specifically, Negative Temperature Coefficient (NTC) thermistors are frequently employed due to their predictable response and sensitivity across a broad temperature range, crucial for freezer applications.

Occasionally, older models might incorporate thermocouples, though thermistors are now the industry standard for precision. The sensor’s placement within the freezer is also critical; typically located near the evaporator coil to monitor air temperature, ensuring optimal defrost cycle initiation and termination. Proper sensor selection and placement are vital for maintaining consistent and accurate temperature control within the True freezer environment.

Calibration Steps for Accurate Readings

To calibrate the temperature display, access the controller’s settings menu – typically by pressing and holding the ‘Set’ button until the temperature reading begins to blink. Utilize a calibrated reference thermometer, placed within the freezer, ensuring it doesn’t contact the evaporator coil. Compare the reference thermometer’s reading with the freezer’s digital display.

Employ the up/down arrow buttons to adjust the displayed temperature until it matches the calibrated reference thermometer. Confirm the calibration by pressing ‘Set’ again. Repeat this process if necessary to achieve optimal accuracy. Regular calibration, ideally every six months, is recommended to compensate for sensor drift and maintain precise temperature control. Document calibration dates and adjustments for future reference and troubleshooting purposes.

Troubleshooting Inaccurate Temperature Displays

If the temperature display is inaccurate, first verify the sensor is securely connected to the controller. Check for any physical damage to the sensor or wiring. Ensure proper airflow around the sensor, as obstructions can cause false readings. Begin by recalibrating the unit following the outlined calibration steps, using a certified reference thermometer.

If recalibration fails, inspect the evaporator coil for excessive ice buildup, which can affect sensor readings. A malfunctioning defrost cycle may be the cause. Examine error codes for clues related to sensor failures or controller issues. If problems persist, consider a faulty temperature sensor requiring replacement. Always consult the error code section of this manual or contact technical support for further assistance.

Advanced Settings and Parameters

Accessing advanced settings allows fine-tuning of freezer operation. Cycle rate adjustment controls the frequency of compressor cycles, impacting energy consumption and temperature stability. Lower rates reduce cycling but may compromise temperature consistency. Evaporator fan control settings manage fan operation during defrost and normal running, optimizing defrost efficiency and preventing temperature fluctuations.

Compressor control parameters, including cut-in and cut-out pressures, influence compressor performance and lifespan. Adjust these cautiously, referencing the manufacturer’s specifications. Incorrect settings can lead to compressor damage or inefficient operation. These advanced parameters require a thorough understanding of refrigeration systems; improper adjustments may void warranties. Always document any changes made for future reference and troubleshooting.

Cycle Rate Adjustment

The cycle rate parameter dictates how frequently the compressor cycles on and off. A slower cycle rate, achieved by increasing the minimum run time, reduces compressor starts and stops, potentially extending its lifespan and lowering energy consumption. However, it can lead to wider temperature swings within the freezer. Conversely, a faster cycle rate, with shorter minimum run times, maintains a more consistent temperature but increases wear and tear on the compressor.

Optimal cycle rate depends on the freezer’s application and load. Freezers with frequent door openings or large product loads benefit from faster rates. Those with stable loads can operate efficiently with slower rates. Careful monitoring of temperature fluctuations is crucial when adjusting this setting. Always consult the manufacturer’s recommendations before making significant changes.

Evaporator Fan Control Settings

True freezer controllers offer options for managing evaporator fan operation, impacting temperature uniformity and defrost efficiency. Typically, settings allow for continuous fan operation or fan cycling. Continuous fan operation ensures consistent temperature distribution throughout the freezer, minimizing temperature gradients. However, it can increase energy consumption and potentially lead to moisture buildup on the evaporator coil.

Fan cycling, where the fan turns off during compressor off-cycles, reduces energy use and minimizes coil frosting. However, it may result in slight temperature variations. Some controllers offer adjustable fan speeds for fine-tuning performance. Proper evaporator fan control is vital for maintaining product quality and preventing ice buildup, which can hinder cooling efficiency. Monitor temperature distribution to optimize these settings.

Compressor Control Parameters

True freezer controllers manage compressor operation through several key parameters, directly influencing cooling capacity and energy efficiency. These include the cut-in and cut-out temperature settings, defining the temperature range where the compressor cycles on and off. Adjusting these settings impacts temperature stability and compressor run-time.

Some controllers feature adjustable cycle rates, controlling how frequently the compressor starts and stops. A slower cycle rate reduces wear and tear on the compressor, while a faster rate provides quicker temperature recovery. High and low-pressure cut-out settings protect the compressor from damage due to abnormal refrigerant pressures. Proper configuration of these parameters is crucial for reliable freezer operation and prolonged compressor life. Careful monitoring and adjustment are recommended.

Error Codes and Diagnostics

True freezer controllers utilize error codes to signal malfunctions within the system, aiding in efficient troubleshooting. Common codes indicate sensor failures (temperature probe issues), defrost system errors (heater or timer malfunctions), or compressor problems (start-up failures or overloads). A detailed error code list is typically found within the controller’s technical documentation.

Diagnostic procedures involve first recording the error code, then checking associated components. For sensor errors, verify wiring and sensor integrity. Defrost errors require inspection of the heater, defrost timer, and termination thermostat. Compressor errors may necessitate checking the overload protector, start capacitor, and refrigerant levels. Always consult the service manual for specific troubleshooting steps and safety precautions before attempting repairs. Ignoring error codes can lead to further damage.

Common Error Codes and Their Meanings

True freezer controllers display specific error codes to pinpoint system issues. “E1” often indicates a temperature sensor failure – a disconnected or faulty probe. “E2” typically signals a defrost heater malfunction, meaning the heater isn’t warming up during the defrost cycle. “E3” usually points to a defrost termination thermostat problem, preventing the cycle from ending. “E4” can signify a door switch issue, falsely indicating the door is open.

“E5” frequently relates to a compressor failure, potentially due to overload or start-up issues. “E6” may indicate a low or high temperature alarm condition, even without a setpoint breach. These codes are crucial for targeted diagnostics. Refer to the specific model’s service manual for a complete list and detailed explanations, as code meanings can vary slightly between controller versions.

Diagnostic Procedures for Error Resolution

Upon encountering an error code, begin with a visual inspection. Check wiring connections to the affected component (sensor, heater, thermostat, switch) for looseness or damage. Use a multimeter to verify component functionality – resistance checks for heaters and sensors, continuity for switches. If an “E1” sensor error occurs, confirm proper probe placement and insulation. For “E2” heater faults, test the heater’s resistance and voltage supply.

“E3” thermostat issues require verifying thermostat closure at the appropriate temperature. Document all test results. If the problem persists, consult the service manual for specific troubleshooting flowcharts. Consider component replacement if testing confirms a failure. Always prioritize safety and disconnect power before performing electrical tests.

Contacting Technical Support

For issues beyond your troubleshooting capabilities, contacting True’s technical support is crucial. Have your freezer’s model and serial number readily available, alongside a detailed description of the problem, including any error codes displayed. Document all troubleshooting steps already performed, and the results obtained. This information significantly speeds up the diagnostic process.

True’s support team can provide advanced diagnostics, wiring diagrams, and component specifications. You can typically reach them via phone or email, details of which are found on True’s official website or within the freezer’s documentation. Be prepared to answer questions about the freezer’s operating environment and recent maintenance. Prompt and accurate information ensures efficient resolution.